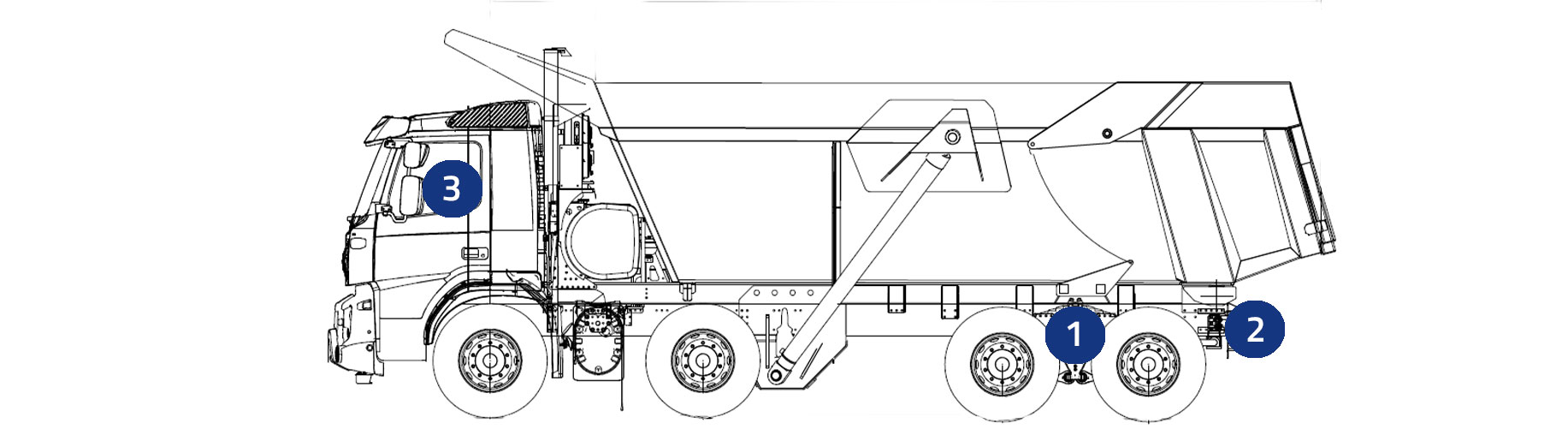

The widespread haul truck is equipped with a 38 tonne tandem axle. The strength of this tandem axle is improved by BAS Mining Trucks. The axles are placed further apart. This way, more space is created to mount bigger and wider tires. This brings more stability during driving and unloading on the one hand. On the other hand this results in more carrying capacity, resulting in 8x4 tipper trucks with a capacity of 24 m3 and a net payload of 45 tonnes.

The new widespread haul trucks have a top speed of 50 km/h and can operate on a gradeability up to 15%. To increase efficiency of your operation, more options like payload measurement system, inclinometer and BAS Fleet Connect are available.